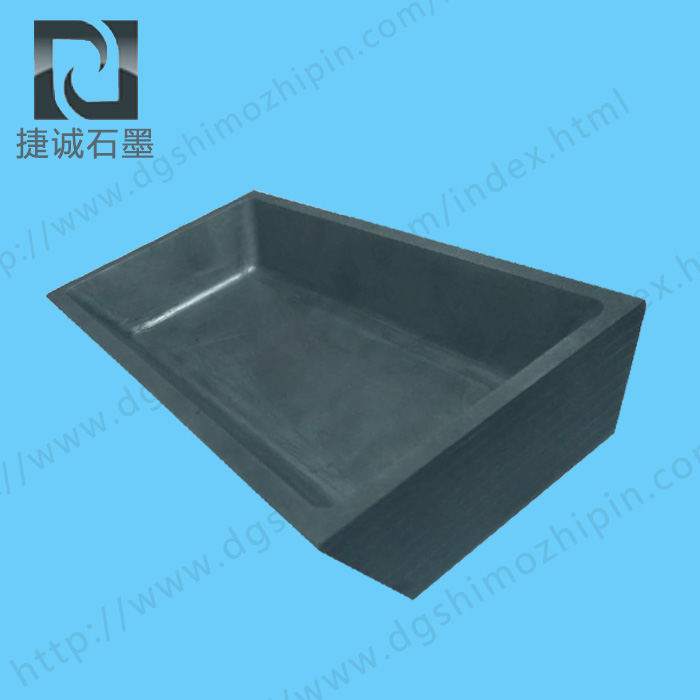

The sintering of lithium battery materials needs a high-temperature and corrosion-resistant material to be sintered, so Xiaobian thought of a graphite product that is very suitable for the sintering of lithium batteriesGraphite saggerIt can also be called a graphite material box. For the sagger used for sintering lithium battery materials, it needs to be matched with a bottom plate and a cover plate The advantages of using this product lie in its long service life, superior cost performance, low impurity content, high temperature resistance and oxidation resistance, extreme resistance to metal solution corrosion and other characteristics, and high user satisfaction.

At present, according to the density and shape of products, there are sintering method, melting casting method and melting blowing method in industry. The sintering method is to pre burn some raw materials into mature materials, crush and screen them, then mix them with raw materials according to a certain proportion, and then shape, dry and burn them. The purpose of raw material pre firing is to burn away the moisture, organic impurities and sulfate decomposing gas in order to reduce the sintering shrinkage of products and ensure the accuracy of product outline dimensions. The raw materials need to be screened after crushing and grinding, because the billets are graded by powders with different particle sizes, which can ensure close packing and obtain a compact billet.

The key point is that the polishing of raw materials for making saggers is usually carried out outside the house. The method is to pour graphite on the ground, make it into a thin layer overlapping stack, and then cut it one by one with a shovel, and then add water to knead it. After kneading, it can be used for making graphite saggers. Dongguan Jiecheng graphite products Co., Ltd. has very mature technology in the field of producing graphite saggers. Welcome to process.

Graphite saggerPrecautions for sintering use: measure and analyze the chemical mineral composition and crystal morphology. In order to improve the quality of the graphite sagger, attention should be paid to the following aspects: the clinker should be fully sintered to achieve the highest possible density, the clinker should have a certain particle gradation, wet ball milling should be used for batching, and under the condition of certain use strength, there should be appropriate pores and microcracks in the microstructure of the product, the calcination temperature should be suitable, and the shape and size of the product should also be noted. Changes of graphite sagger during use: sagger is a kiln tool that is repeatedly used under the action of thermal load. Service life is the main technical and economic index of sagger. Load softening point fire resistance capacity air porosity thermal shock resistance strength various scientific testing methods are used to measure the overall dimensions of saggers in order to observe the changes of saggers during use.

Company telephone: 0769-89392518

Company fax: 0769-89392508

Mr. He: 13602898588

Address: No. 3, Caimei 2nd Road, longjiantian, Huangjiang Town, Dongguan City