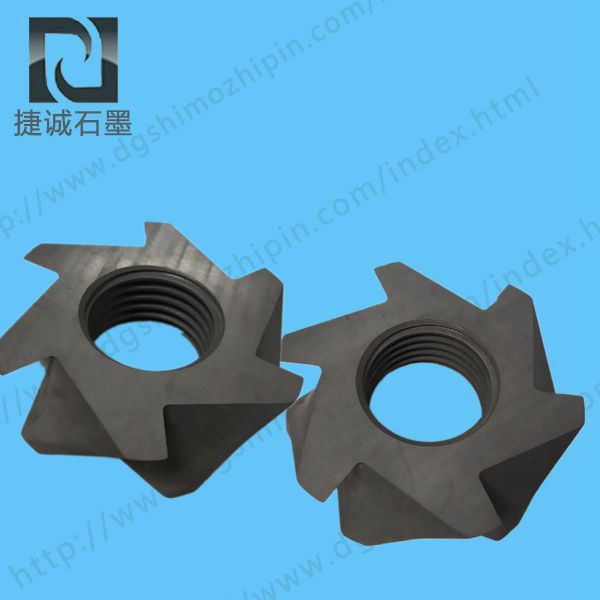

The working principle of graphite rotor for graphite processing is that the rotating rotor breaks the nitrogen (or argon) blown into the aluminum melt into a large number of dispersed bubbles, and disperses them in the metal liquid. Bubbles in the melt absorb hydrogen in the melt by gas partial pressure difference and surface adsorption principle, adsorb oxidation slag, and are brought out of the melt surface with the rise of bubbles to purify the melt. Due to the fine dispersion of bubbles, they are uniformly mixed with the rotating melt, and then rotate to slowly float in a spiral shape. The contact time with the melt is long, and the gas flow generated by the continuous linear rise will not be formed, thus significantly improving the purification effect.

Product features:

1. Rotary refining degasser is divided into movable and fixed modes, which are applicable to different operating environments.

2. The degassing rate is more than 50%, which shortens the smelting time and reduces the production cost.

3. It is suitable for purifying the molten aluminum in crucible furnace, ladle and static box