Dongguan graphite mould processing enterprise

Graphite mold factory, a professional graphite mold manufacturer, produces graphite molds with first-class quality and first-class price.

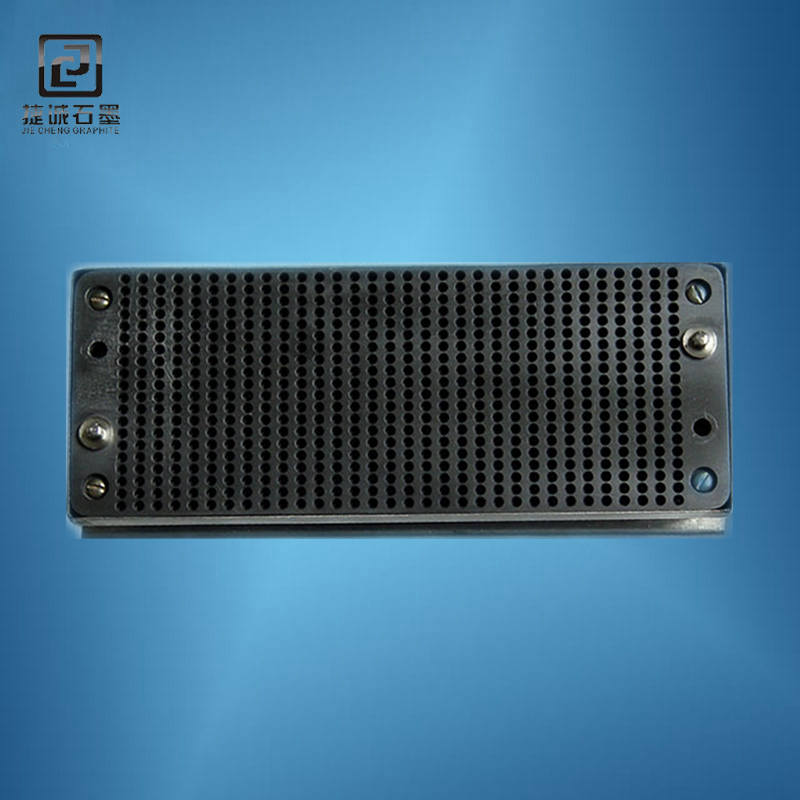

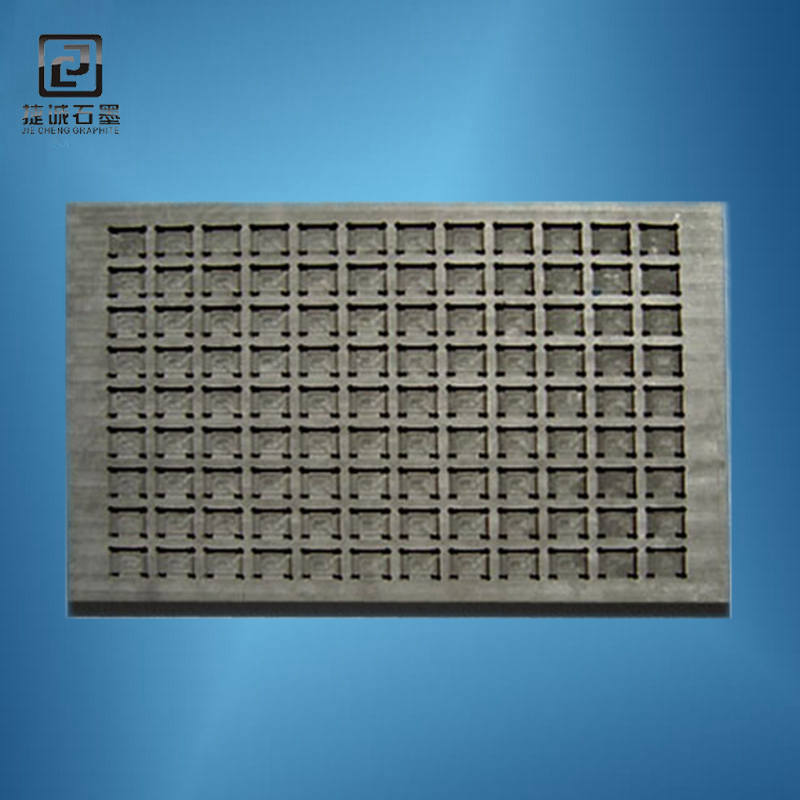

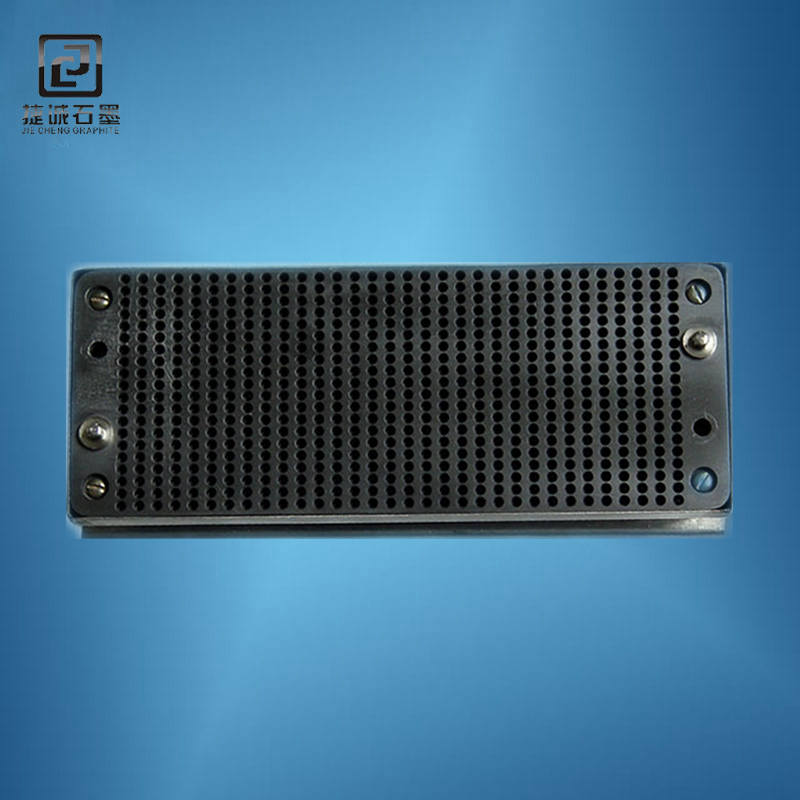

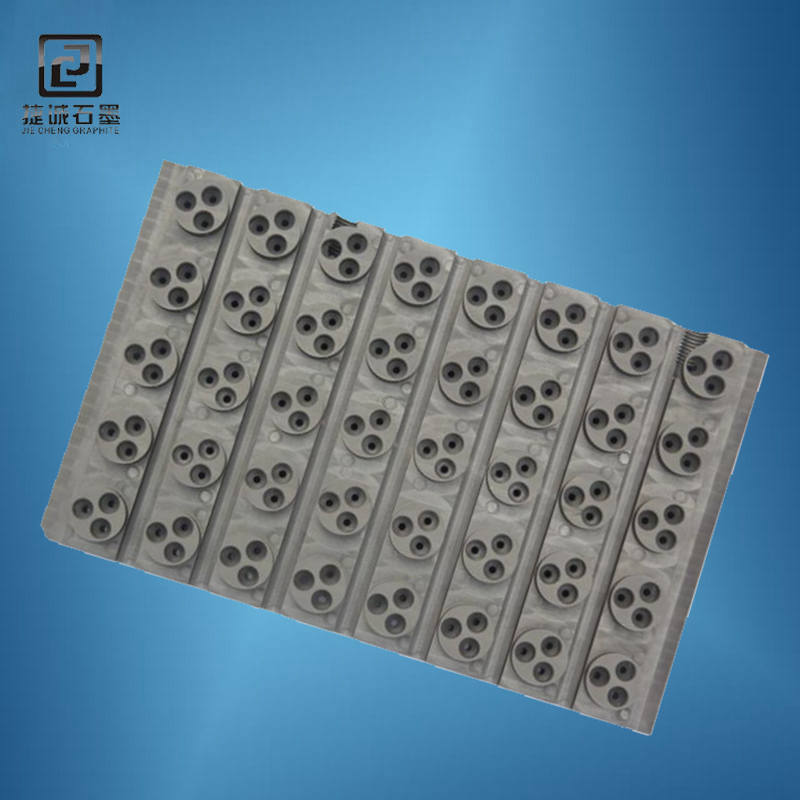

Excellent performance of graphite mold: 1. Excellent thermal conductivity and conductivity 2. Low coefficient of linear expansion good thermal stability and heat shock resistance 3. Chemical corrosion resistance, not easy to react with most metals 4. At high temperature (above the sintering temperature of most copper matrix 800 ℃) the strength increases with the increase of temperature 5. Good lubrication and wear resistance 6. Easy to process, good machinability, can be made into complex shapes High precision mold.

Dongguan Jiecheng graphite products Co., Ltd. specializes in the production of graphite molds, special-shaped molds and hollow molds. Welcome new and old customers to order

Source: graphite mold, special-shaped mold, hollow mold http://www.jasengd.com/

Nowadays, the graphite mold industry plays a vital role in human life and development. The development of many industrial sectors (such as Electromechanical, automobile, home appliance light industry, electrical instruments, communication, ordnance, etc.) depends on the technical improvement and development of the mold industry. All countries in the world have invested a large amount of human and financial resources to develop the graphite mold industry. For example, sigli in Germany and Toyo carbon in Japan have achieved a leading position in the international graphite mold industry. China also attaches great importance to the development of the mold industry. The level of mold production technology has become an important symbol to measure the level of a country's product manufacturing, because mold determines the quality, efficiency and development ability of new products to a large extent. Since 1997, China's relevant departments began to attach importance to and support the development of the graphite mold industry, and vigorously supported the development of China's local enterprises in the graphite mold industry. Now, they have made good achievements and contributed to China's export foreign exchange income.

Source: graphite mold | profiled mold | hollow mold http://www.jasengd.com/

Related tags: graphite mold, graphite mold manufacturer, graphite mold supply,

Analysis and opinion of Dongguan Jiecheng graphite mould factory on accelerating structural adjustment of graphite mould and winning the market

Graphite mold for continuous casting and semi continuous casting of non-ferrous metals: in recent years, advanced production methods such as directly continuous (or semi continuous) production of bars or pipes from molten metal are being promoted at home and abroad. This method has been used in copper, copper alloy, aluminum and aluminum alloy in China. Artificial graphite is considered as the most suitable material for continuous casting or semi continuous casting molds of non-ferrous metals. The production practice has proved that the graphite mold not only improves the casting speed due to its good thermal conductivity (which determines the solidification speed of metal or alloy) and good self-lubricating performance, but also can be directly processed in the next process due to its accurate size, smooth surface and uniform crystal structure. This not only greatly improves the yield and reduces the waste loss, but also greatly improves the product quality. Continuous casting methods include vertical continuous casting method and horizontal continuous casting method. Mold is the basic process equipment widely used in industrial production, and mold industry is the basic industry of national economy. In modern industrial production, stamping, forging, die-casting, extrusion, plastic injection or other forming methods are widely used for product parts, which are matched with forming dies to form and process blanks into parts that meet product requirements. All kinds of tools and products we use in our daily production and life, ranging from the base of machine tools and the shell of machine bodies to a embryonic head screw, button and the shell of various household appliances, are closely related to the mold. The shape of the mold determines the appearance of these products, and the processing quality and accuracy of the mold also determines the quality of these products. In recent years, with the rapid development of the mold industry, graphite materials, new processes and increasing mold factories continue to impact the mold market. Graphite has gradually become the preferred material for mold manufacturing due to its good physical and chemical properties.

Keywords: Dongguan graphite mold processing, graphite mold processing, graphite mold processing enterprise, graphite mold processing factory, graphite mold picture, graphite mold price, graphite mold factory, graphite mold processing factory, graphite mold processing CNC & nbsp& nbsp;