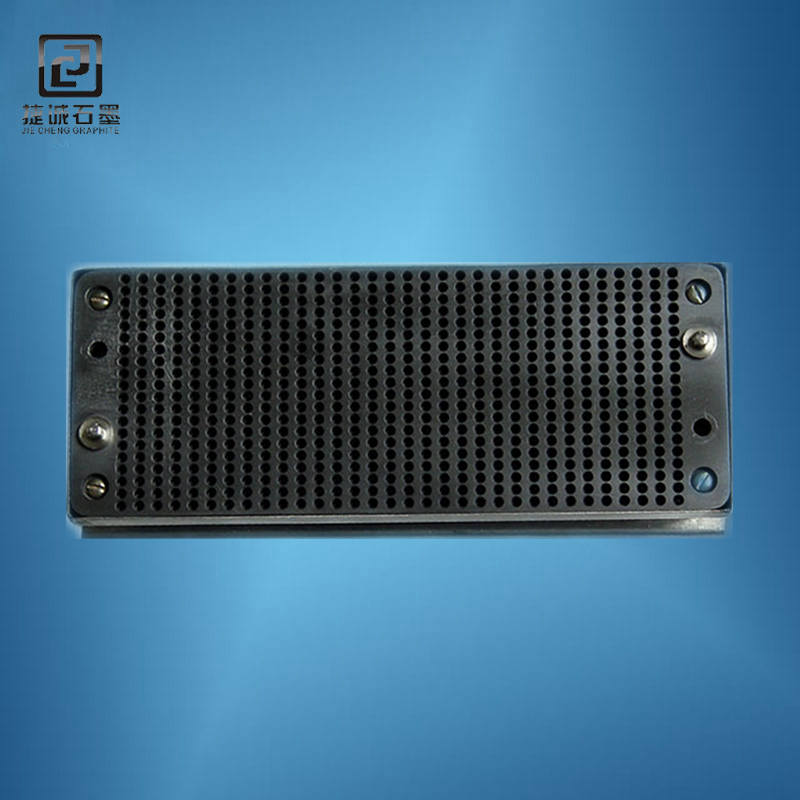

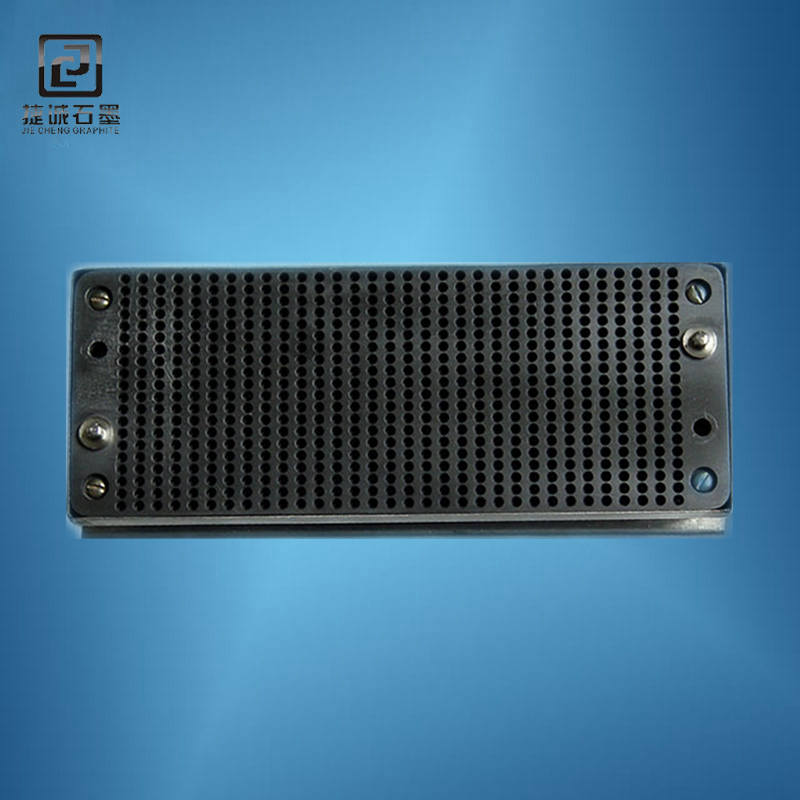

Graphite mold manufacturers, graphite sintered molds are widely used in the production of semiconductor packaging through glass, metal, brazing and other methods. They are widely used in electronic production enterprises, component manufacturers, diode production and assembly. The mold processing accuracy is high, the graphite material is superior, the dust is less, the oxidation resistance is good, and the temperature is uniform. The diode products produced with graphite sintered plates have high pass rate, good verticality, durability, and accurate positioning. The resistance coefficient can ensure correct heating; High abrasion resistance, high machining accuracy and good oxidation resistance. Processing requires extremely high accuracy, and graphite with low wear, high oxygen resistance and carbonization resistance must be used. We can design the mold that you are satisfied with, as well as the tooling fixtures that match the graphite mold, such as tin stained fixtures, auxiliary weights, vacuum suction cups, etc& nbsp;& nbsp;

Graphite mold materials used for diamond tool manufacturing are mainly graphite materials with ultra-fine particle structure, high purity and high graphitization degree, and their average particle size is required to be less than 15 μ m. Even 10 μ M U.M or less, medium pore size less than 2 μ m。 The graphite mold made of this carbon material has the advantages of small porosity, compact structure, high surface finish and strong oxidation resistance. The average service life can reach 30-40 times.

The electronic sintered graphite mold and support for transistors can be manufactured by using the characteristics of artificial graphite with minimal thermal deformation. It has been widely used and has become an indispensable material for the development of semiconductor industry.

The electronic sintered graphite mold used for hot press sintering diamond tools plays the dual role of heating element and mold support in the manufacturing process of diamond tools. The quality of graphite mold directly affects the dimensional accuracy and appearance shape of diamond tools.

In addition, graphite molds are also used for cast iron molds, durability molds for various non-ferrous metals, cast steel molds, heat-resistant metals (titanium, zirconium, molybdenum, etc.), and thermite welding molds for rail welding.

Hot press sintering process requirements: the temperature reaches (1000 ± 2) ℃, the forming pressure is 16 ~ 50MPa, the holding time is 15 ~ 30min, and the environment is non vacuum. Under this working condition, the sintered graphite mold for forming and heating elements is required to have conductivity, high resistivity and sufficient mechanical strength, as well as good oxidation resistance and long service life, so as to ensure the dimensional accuracy and excellent performance of diamond tools.

Diamond Mold requires high hardness, good oxidation resistance and high machining accuracy. The use of high-quality graphite raw materials greatly extends the service life of the mold and improves the oxidation resistance

Dongguan Jiecheng graphite products Co., Ltd. is a production-oriented enterprise with high sales performance of hardware products. Adhering to the strategy of "people-oriented and talent winning" for many years, the company has fully stimulated its talent advantages, and has outstanding talent advantages in R & D, management and sales. The company's products are based on the needs of consumers, based on the market through standardized operation, and with the new concept of innovative management, it achieves good economic benefits and contributes to social development.

Dongguan Jiecheng graphite products Co., Ltd. for the convenience of customers, after purchasing our graphite sintering mold, please pay online; cash payment; For payment by bank transfer, we will deliver the goods within the time agreed by both parties. We abide by national laws and regulations, adhere to market development as the guide, take standardized operation as the fundamental, improve the company's operation mode, adjust the company's industrial structure, establish an effective operation mechanism, constantly expand the company's business scope, and enhance the company's core competitiveness.

Dongguan sintered graphite mold manufacturer, Guangdong graphite sintered mold supplier, in accordance with the actual market demand, our company focuses on producing and operating qualified and compliant products, and updates and improves products in time to meet changing user needs. The spirit of reform, innovation and perseverance, based on the market, diversified and large-scale operation, have created brilliant development achievements of the company. Looking forward to the future, Dongguan Jiecheng graphite products Co., Ltd. will make unremitting efforts, with the goal of going to the international market, continue to provide excellent graphite sintering molds and perfect and reliable services for the vast number of demand groups, and make due contributions to the healthy development of the industry.

Main keywords: sintered graphite mold, electronic mold, electronic sintered graphite mold, graphite mold manufacturer, semiconductor graphite packaging mold, glass off packaging graphite mold, electronic sintered metallurgy tools, graphite metallurgy manufacturers, graphite mold factories