& nbsp;& nbsp; The graphite thermal field for monocrystalline silicon furnace is a comprehensive theory integrating physics, chemistry and geometry. It is formulated by special researchers after years of repeated research and years of experience.

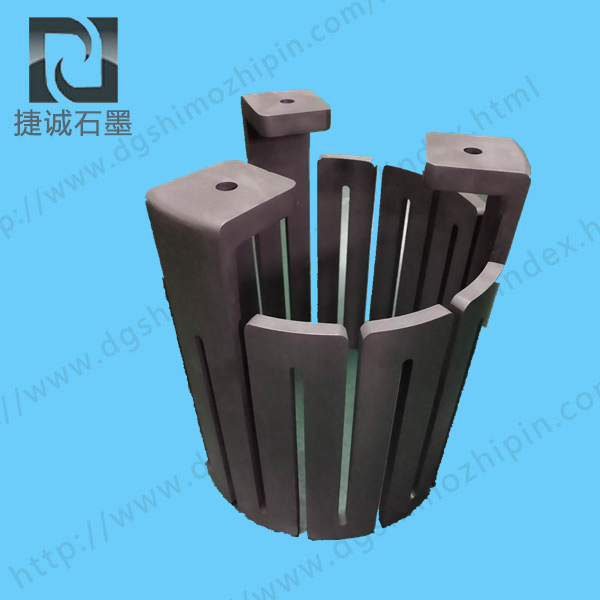

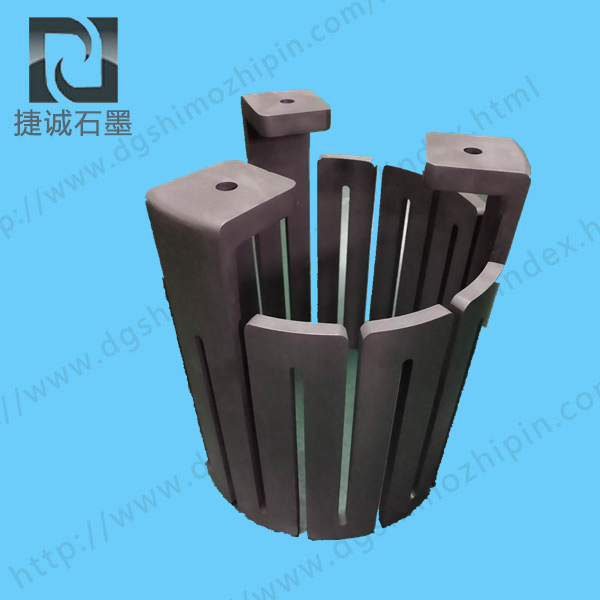

Fine structure medium coarse graphite is used as the bottom guard plate in the heat field. The imported isostatic pressure graphite is used as the heater, crucible, flow guide, support rod and pot support for the thermal insulation cover and upper and lower covers to ensure the strength and purity of the graphite crucible.

Thermal field is one of the important conditions for single crystal silicon crystallization. The gradient distribution of thermal field directly affects whether single crystal can be pulled out and the quality of drawn single crystal. The quality of its material directly affects the life of thermal field. The company has cooperated with Hebei Jinglong group, the earliest monocrystalline silicon manufacturer in China, for more than ten years. Cooperating with Jinglong group and combining domestic and foreign graphite materials, we have successfully developed 18-22 inch graphite heat field, and established our own graphite heat field production base with Jinglong group. It has been used in many monocrystalline silicon production bases such as Jinglong group for a long time. The graphite materials used and the life of the whole thermal field are affirmed. The following standards are formulated for future production.