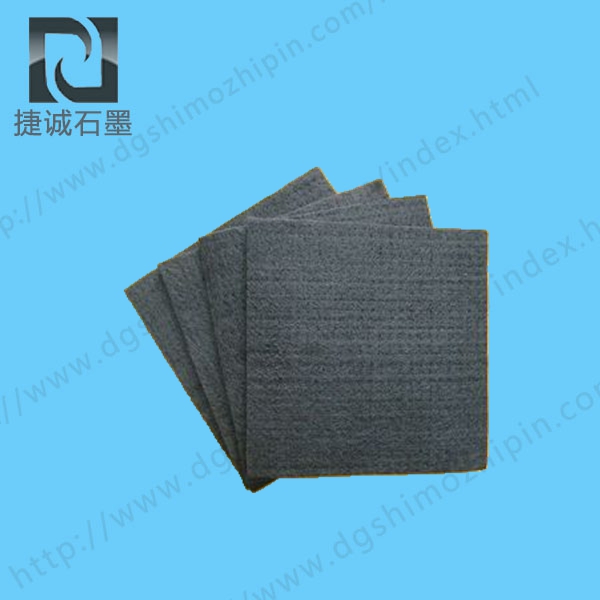

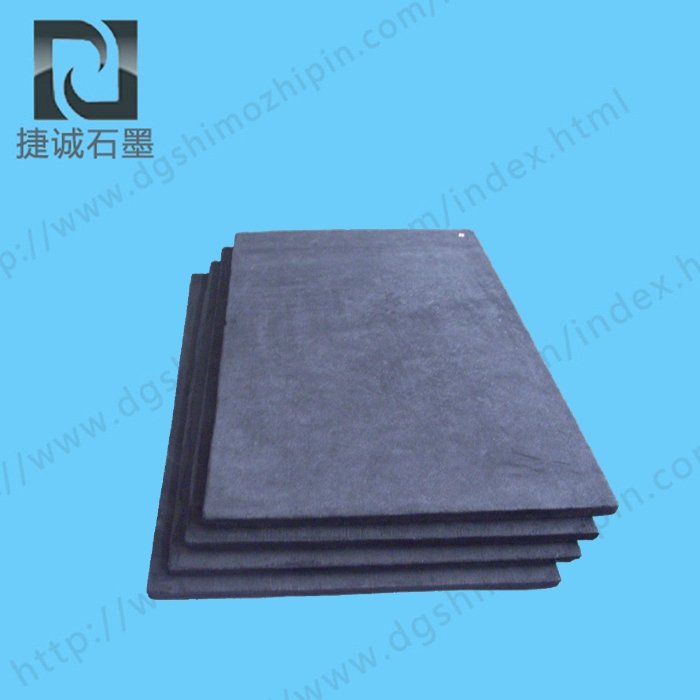

SincerityGraphite feltAccording to the difference of the original felt, it is divided into asphalt based, polyacrylonitrile based ink felt and viscose based ink felt.

Among them, the asphalt represented by Jebsen graphite felt is the mainstream in the insulation industry. The process cuts polyacrylonitrile based carbon felt or viscose based carbon felt to the required size, rolls it into a cylinder, and puts it into a container made of graphite material. The graphite container is placed in a high-temperature furnace (the high-temperature furnace is a graphite tube furnace, an intermediate frequency, a high-frequency induction furnace, or other heating forms of high-temperature furnace). It is heated to 2200 ~ 2500 ° C at a heating rate of 100 ~ 300 ° C / h with vacuum extraction or high-purity inert gas protection, And then naturally cooled to 100 ℃. Polyacrylonitrile based ink felt has stronger strength and stronger oxidation resistance than adhesive based ink felt, but it has poor flexibility, large bulk density and good thermal insulation performance. In addition to the characteristics of high purity, high temperature resistance, corrosion resistance and non melting of block graphite, they also have the advantages of elasticity, arbitrary folding, cutting and sewing with graphite yarn. Graphite felt is mainly used as thermal insulation material for monocrystalline silicon smelting furnace. In the chemical industry, it can be used as a filter material for high-purity corrosive chemical reagents. The temperature of graphite felt can reach about 3000 ℃ in non oxidizing atmosphere.

Jebsen graphite carbon felt is a graphite felt after high-temperature treatment above 2000 ℃ in vacuum or inert atmosphere. The carbon content is higher than that of carbon felt, reaching more than 99%. Graphite felt can be divided into asphalt based, polyacrylonitrile based ink felt and viscose based ink felt according to the original felt.

Among them, asphalt represented by Jebsen graphite is the mainstream in the thermal insulation industry. In Europe and the United States, the thermal insulation felt is basically dominated by adhesives, while most of China's domestic materials are polypropylene based. The process is to cut polyacrylonitrile based carbon felt or viscose based carbon felt to the required size, roll it into a cylinder, and put it into a container made of graphite material. The graphite container is placed in a high-temperature furnace (the high-temperature furnace is a graphite tube furnace, an intermediate frequency, a high-frequency induction furnace, or a high-temperature furnace of other heating forms). It is heated to 2200 ~ 2500 ℃ at a heating rate of 100 ~ 300 ℃ / h with vacuum extraction or high-purity inert gas protection, and then cooled naturally to 100 ℃. Polyacrylonitrile based ink felt has stronger strength and stronger oxidation resistance than adhesive based ink felt, but it has poor flexibility, large bulk density and good thermal insulation performance. In addition to the characteristics of high purity, high temperature resistance, corrosion resistance and non melting of block graphite, they also have the advantages of elasticity, arbitrary folding, cutting and sewing with graphite yarn. Graphite felt is mainly used as thermal insulation material for monocrystalline silicon smelting furnace. In the chemical industry, it can be used as a filter material for high-purity corrosive chemical reagents. The temperature of graphite felt can reach about 3000 ℃ in non oxidizing atmosphere.

Tel: 0769-89392518

Mobile wechat: 13922517582

Contact: Li Sheng