Introduction and selection guide of vacuum heat treatment furnace:

1. Vacuum heat treatment technology is a high-precision, high-quality, energy-saving, clean and pollution-free processing and manufacturing technology in material modification. It is an important field of manufacturing technology and a hot field of process development.

2. Advantages of vacuum heat treatment:

2.1 prevent oxidation, the surface does not oxidize, decarbonize and has the effect of reducing and removing rust, eliminating the surface grinding process;

2.2 vacuum degassing can improve the surface purity of materials, improve the fatigue strength, plasticity and toughness of materials, and improve the corrosion resistance;

2.3 degreasing function: remove residual oil and improve product quality;

2.4 there is no danger of hydrogen embrittlement in the processed workpiece to prevent the surface embrittlement of titanium and refractory metal;

2.5 vacuum heating is evenly heated, with small internal and external temperature difference and thermal stress; The design structure of the vacuum furnace ensures that the workpiece does not move violently, so it will not deform due to external force;

2.6 low power consumption, energy consumption is only about 50% of that of conventional heat treatment furnace, saving production cost;

2.7 safe operation, high degree of automation, good working environment, pollution-free and pollution-free;

3. Application of vacuum heat treatment furnace:

It is mainly used for quenching (oil quenching and gas quenching), tempering, annealing, carburizing, ionizing (carbon, nitrogen and metal), dehydroxylation and vacuum reduction of die steel, high-speed steel, alloy structural steel, bearing steel and elastic alloy materials.

4. Classification of vacuum heat treatment furnace

Heat treatment furnaces are mainly divided into vqg series vacuum gas quenching furnace, VOG series vacuum oil gas quenching furnace, VTF series vacuum tempering furnace and VAF series vacuum annealing furnace.

5. Selection guide of vacuum heat treatment furnace:

5.1 selection of installation mode of vacuum heat treatment furnace: the vacuum heat treatment furnace developed by our company is divided into horizontal and vertical furnaces, and the vertical furnace is divided into upper discharging and lower discharging structures. The selection basis is mainly determined by the type, shape or placement of the processed products.

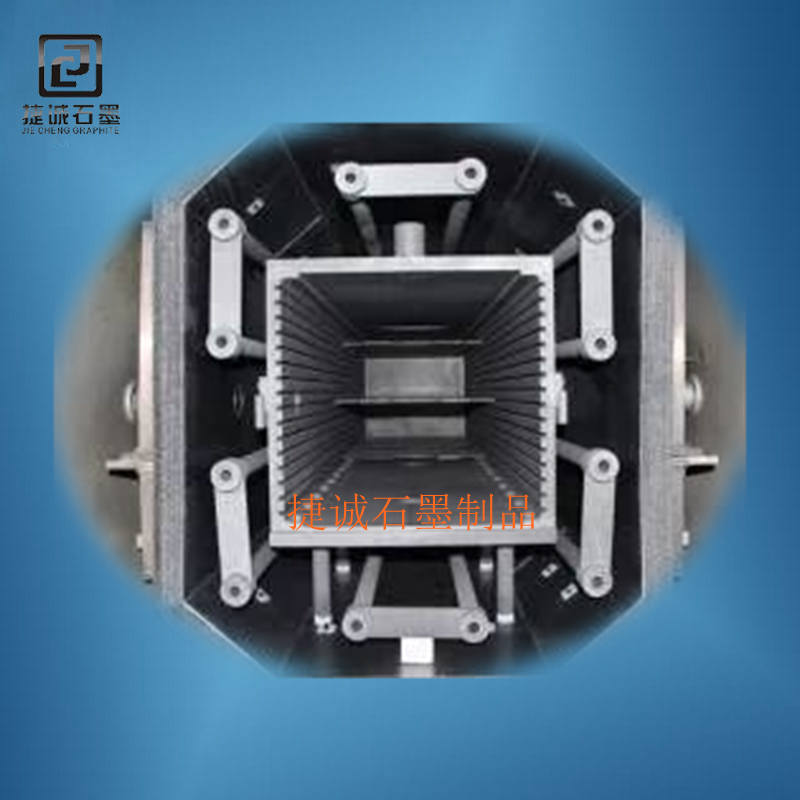

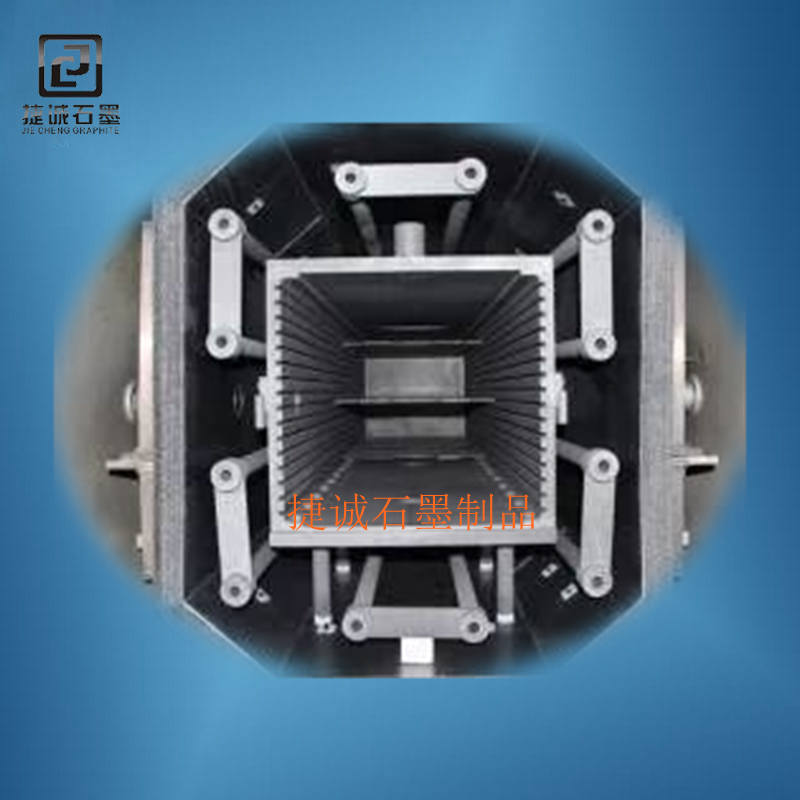

5.2 selection of heating components: the heat transfer mode from the heating element of the vacuum heat treatment furnace to the workpiece is different from that of the ordinary electric heating furnace, and radiation heat transfer is the main one. The heating components of the vacuum heat treatment furnace produced by our company mainly include nickel chromium, high-temperature molybdenum, graphite and graphite belt (plate). Nickel chromium is mainly used in vacuum furnace with temperature below 1000 ℃, high-temperature molybdenum is used in heat treatment furnace with temperature below 1600 ℃, and graphite and graphite strip (plate) can be used in vacuum heat treatment furnace with temperature below 2300 ℃. The selection of heating components is mainly based on the heat treatment temperature and the physical and chemical characteristics of the product.

Keywords: vacuum furnace graphite, vacuum furnace graphite accessories, vacuum furnace heating pipe, graphite heating pipe, graphite air pipe, graphite nut, graphite plug, graphite sleeve, graphite sleeve & nbsp& nbsp;