Introduction to soaking plate (vapor chamber)

Basic principle and application of soaking plate (vapor chamber)

The soaking plate is a vacuum cavity with microstructure on the inner wall. When heat is conducted from the heat source to the evaporation area, the inside of the cavity

The working medium will start to gasify in the liquid phase in the low vacuum environment. At this time, the working medium absorbs

Thermal energy and rapid volume expansion, the gas-phase working medium will soon fill the whole cavity, when the gas-phase working medium contacts a

Condensation occurs in a relatively cold area, and is released by condensation and accumulated during evaporation

The condensed liquid-phase working medium will return to the evaporation heat source through the capillary phenomenon of the microstructure

It will be carried out repeatedly in the cavity, which is the operation mode of the soaking plate. And because the working medium is micro agglomerated during evaporation

The structure can generate capillary force, so the operation of the soaking plate can be unaffected by gravity.

The principle and theoretical framework of soaking plate and heat pipe are the same, except that the heat conduction mode is different, and the heat of heat pipe

The conduction mode is one-dimensional, which is the linear heat conduction mode, while the heat conduction mode of the soaking plate is two-dimensional, which is

Surface heat conduction mode.

?? Cavity material

C1100 toughened copper smelting

?? Working medium

Water (purified and degassed)

?? Microstructure

The single layer or multi-layer copper mesh is connected with each other by diffusion bonding, and is closely connected with the cavity

The effect is the same as that of copper powder sintering.

Microstructure features of copper mesh after bonding:

1. The aperture is about 50 μ M to 100 μ m

2. Microstructures with different pore sizes in the upper and lower layers can be fabricated, which will provide improved microstructure efficiency.

3. Microstructures with multiple different aperture regions on the same plane can be fabricated

4. Application features

Different microstructures can be fabricated in the evaporation area and the condensation area to meet the needs of the product. The company's

There are two basic combinations in the development area and nine basic combinations in the condensation area, which can be used according to each other's needs

Use together.

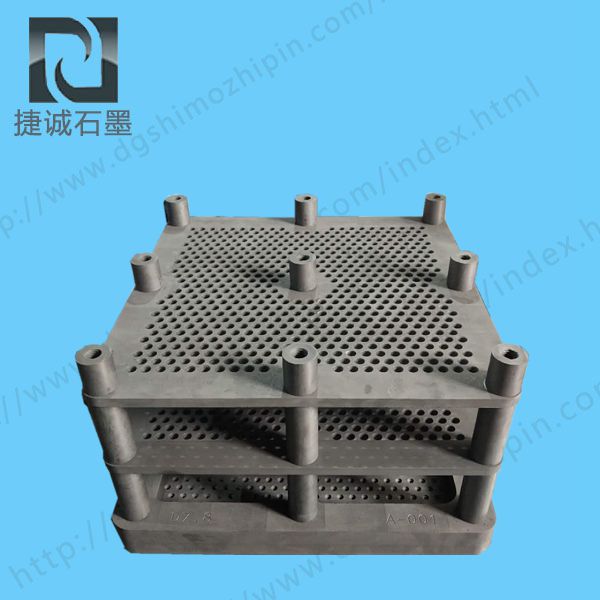

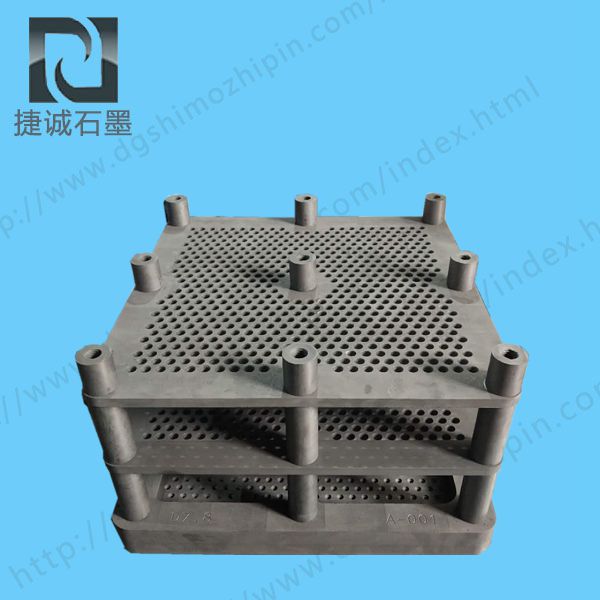

?? Shape and size

Up to 400mm x 400mm, no shape limitation.

?? thickness

3.5mm to 4.2mm, the thinnest can be 3mm

?? Support and pressure resistance

There is a copper column connecting the upper and lower covers inside, with a withstand voltage of up to 3.0kg/cm2

(internal pressure of about 130 ° C environment)

?? perforation

The soaking plate can be perforated.

?? planeness

According to different cavity wall thickness and copper pillar design, the heat source contact surface can reach 50 μ M) other parts can reach

one hundred μ m. The thickness of copper sheet and the number of copper columns will affect the efficiency and flatness of soaking plate

?? Post processing process

The fins can be welded after the soaking plate test is completed, which will not affect the performance of the soaking plate and improve the product quality

Guaranteed, more flexible processing.

The company's soaking plate manufacturing technology is based on product efficiency and quality requirements, with the feasibility and cost of mass production

Quantity, developed mass production technology,

It has the following technical features.

Microstructure of combined copper mesh

According to the characteristics of evaporation zone and condensation zone, copper mesh microstructures with different pore diameters can be combined in soaking plate. On the same floor

The microstructure with different pore size in the upper and lower layers can be produced in the microstructure of the sintered microstructure.

?? Diffusion bonding

High order diffusion bonding technology can complete the mutual bonding of two metals without any solder. After bonding, two pieces

The metal will be integrated into one, and the company uses this technology to complete the surrounding of soaking plate, microstructure and copper

The leakage rate is lower than 9 x 10-10 mbarl / sec and the tensile force can reach 3kgs / cm2,

It fully meets the requirements of soaking plate products and has no environmental problems.

?? Vacuum degassing water injection

It can control the cleanliness and vacuum inside the soaking plate to ensure consistent product performance and stable quality.

?? Vacuum high frequency high cycle welding

Used for filling microtubule welding, high cycle heating has the characteristics of short heating time and concentrated temperature range

The brazing of the filling pipe can be completed effectively and quickly, and can be carried out in a vacuum environment

Prevent oxidation inside the cavity during welding.

?? Leak detection

To ensure the airtightness of the product, there are two kinds of leak detection (1) positive pressure leak detection (2) negative pressure leak detection (helium leak detection).

?? Flexible and reliable product design

Can be designed according to efficiency and cost requirements