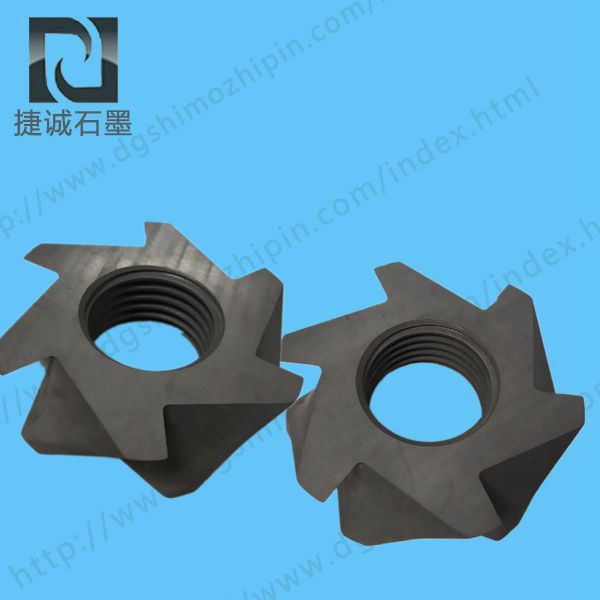

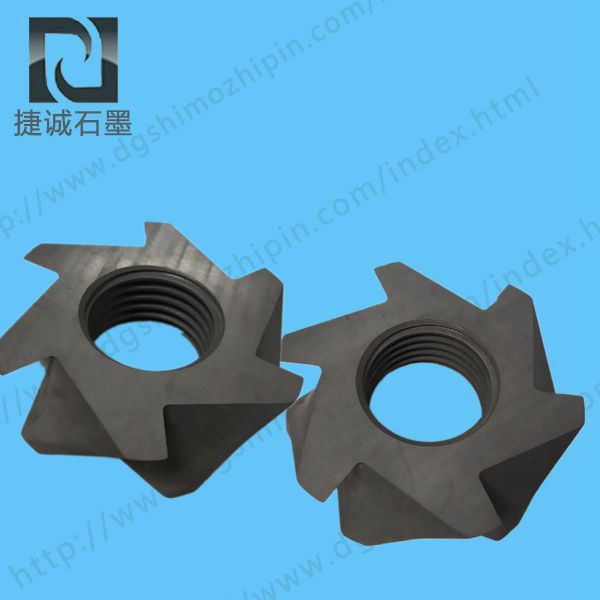

High temperature resistant graphite degassing rotor,

Application: antioxidant graphite rotor

Used in aluminum, zinc and other melting and casting industries. Nitrogen, argon, carbon tetrachloride and other gases are sprayed into the molten metal through the graphite rotor to play the role of dehydrogenation and slag removal, so as to eliminate structural defects such as pores and improve the internal quality of castings.

Performance characteristics:

● use high-quality graphite blank for processing.

● according to the user's use conditions, special anti-oxidation process is adopted for treatment, which can multiply the service life.

Material description: domestic isostatic pressure high-purity graphite material

Dimensions:

● rotor rod:( φ 50- φ 150) × (600-900)mm

Rotor head: φ 100- φ 230mm

● or processed according to user requirements.