Now graphite plays an important role in many industries and is a very important raw materialGraphite processingWhat are the methods? Next, Xiaobian will introduce to you:

1. Mineral processing method of crystalline graphite

Crystalline graphite has good natural floatability. In China, flotation is basically used for beneficiation. Since the size of graphite flakes is one of the most important quality indicators, multi-stage grinding and multiple separation processes are adopted in the separation method to select large flake graphite as soon as possible. The commonly used collectors for flotation are kerosene, diesel oil, etc., the foaming agents are No. 2 oil, No. 4 oil, etc., the regulators are lime and sodium carbonate, and the inhibitors are water glass.

2. Purification and processing of graphite products

The requirements of modern graphite processing industry for graphite products are developing in two aspects: one is to require large crystal scales to reach high purity, and the other is to require graphite product particles to reach ultra-fine (such as less than 1 μ M or 0.5 μ m)。 China has established graphite purification and fine powder processing production lines in graphite concentrators such as Nanshu, Beishu, Liumao and Xinghe. The purification method is mainly chemical purification. The most mature process for chemical purification of graphite is to melt caustic soda and graphite at 700 ℃, wash them to neutral, and then add hydrochloric acid for treatment and washing, so that the carbon content of graphite can reach 98% - 99%. Some manufacturers also use hydrofluoric acid treatment to produce high-purity graphite.

3. Mineral processing method of Aphanitic Graphite

Aphanitic graphite crystal is very small, so it is also called microcrystalline graphite. Graphite particles are often embedded in clay, and separation is difficult. Due to the high grade of raw ore (generally 60% - 80% carbon)

Therefore, many graphite mines directly crush the mined ores and sell graphite powder products. Hunan Lutang graphite mine once set up a flotation plant to float microcrystalline graphite in the 1950s, but it stopped production because of the high cost. At present, some units are still studying the new flotation process of microcrystalline graphite (such as oil agglomeration flotation).

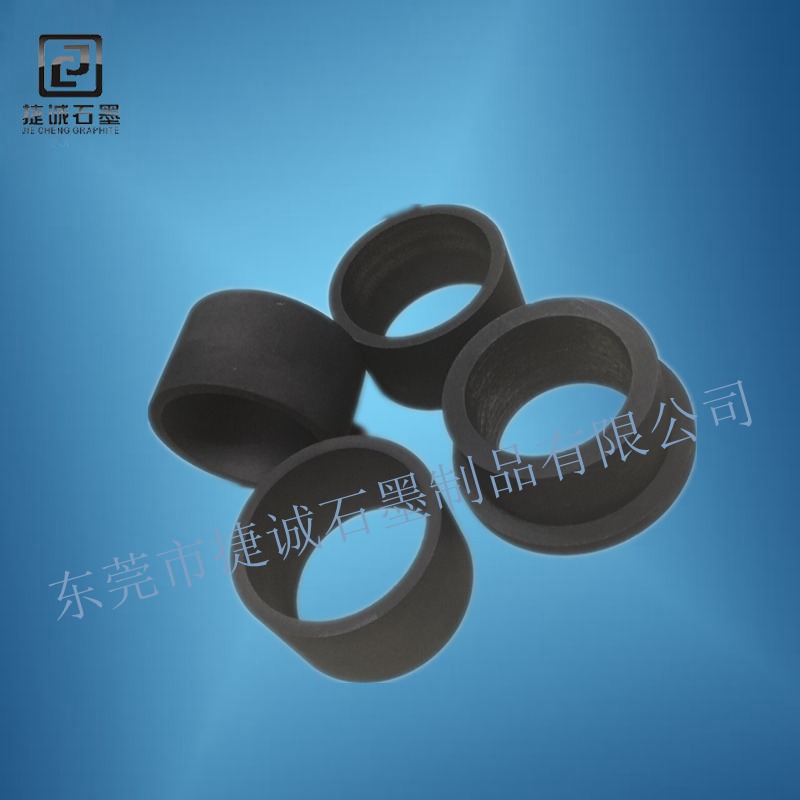

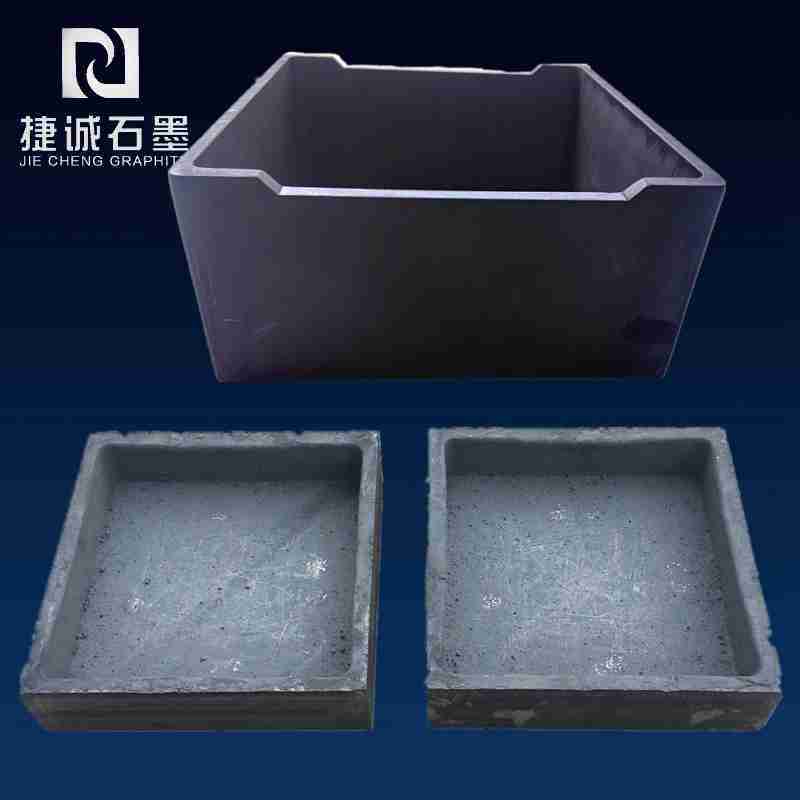

Dongguan Jiecheng graphite products Co., LtdGraphite processingOur products include: graphite blocks, graphite plates, graphite rods, graphite molds, graphite crucibles and other graphite products. Our products are widely used in many industries, such as metallurgy, glass machinery, new materials and new energy. We welcome new and old users to consult and cooperate with us.