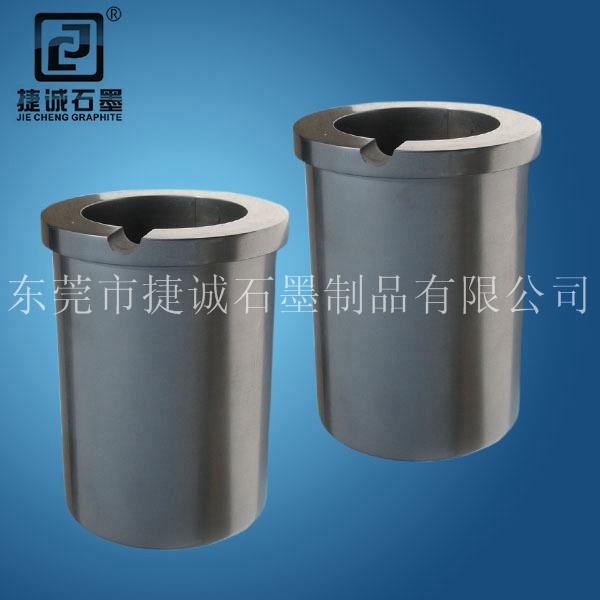

Graphite crucible for melting ironGraphite crucibles for iron smelting and iron smelting are all made of natural graphite with excellent thermal conductivity. The graphite crucible of molten iron shall not be placed on the cold metal table immediately after heating to prevent it from cracking due to rapid cooling. Crucibles are suitable for melting a variety of types and a small number of alloys. If you want to change the type of alloy, you only need to exchange graphite crucibles. Other melting methods, such as reverberatory furnace and non crucible induction furnace, are suitable for large-scale melting of a single alloy. If the type of molten alloy is changed, metal pollution will occur if the refractory lining is not replaced.

Iron oxide graphite crucible is a kind of container with graphite as raw material, so it has very good high temperature resistance and can be used in industrial metal smelting or casting. Take an example in life, you can understand that in rural areas, there are often businessmen who repair aluminum pots or pots. The tool they use is a crucible. Put aluminum sheets into the crucible, heat them with fire, until the aluminum sheets melt into aluminum water, and then pour them into the crack of the pot, After cooling, it can be used. However, iron smelting graphite crucible and silicon carbide crucible are used in industry. Among them, graphite crucible has better thermal conductivity, but it is easy to be oxidized and has a high damage rate. Compared with graphite crucible, silicon carbide crucible has a larger volume and a longer service life.

Iron oxideGraphite crucibleThe price is generally more than three times higher than that of graphite crucibles, and it is also a substitute for crucibles in the metal smelting industry. In order to meet the higher requirements of customers, the company has introduced internationally advanced isostatic pressure crucible forming equipment and technology, selected high-grade refractory raw materials, and developed a new generation of high-quality graphite crucibles for iron making using high-tech formulas. This product has the characteristics of large bulk density, high temperature resistance, fast heat transfer, acid and alkali corrosion resistance, high temperature strength, and high oxidation resistance. The service life is 3-5 times longer than that of the clay graphite crucible.

The models of iron melting graphite crucibles range from 0.5 # - 2500 #, with complete specifications. The products are made of high-quality raw materials and high-tech formula combinations. They have the advantages of low caustic soda, low iron content, high silicon content, high temperature resistance, strong fire resistance, fast heat transfer, high mechanical strength, oxidation resistance, thermal shock resistance, high density, corrosion resistance, low apparent porosity, stable chemical performance, good conductivity, beautiful appearance, durability and other advantages. The quality is stable and reliable, Has been selling well, while supporting productionGraphite cruciblestoneInk plate, graphite cover, graphite tube, graphite pad and other products, and can produce graphite special-shaped products according to user requirements. It is a necessary vessel for melting and casting non-ferrous metals& nbsp;