Self made graphite inlaid self-lubricating copper slider

I have been designing my second lathe. Recently, I found that many friends are making their own machine tools. This is the graphite inlaid self-lubricating copper slider I used on the second lathe, which can increase the service life of the original copper slider by at least twice. There are finished products outside that can be bought, but they are too expensive. I think I can do this myself, so I started to do it. And if I do it myself, I can make different shapes according to my own requirements.

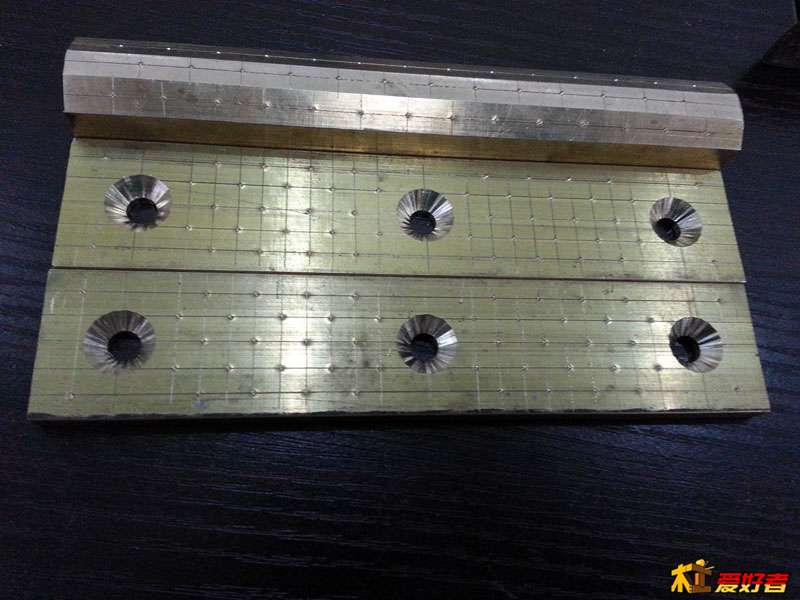

First send two finished product photos in the store

Now I'll start making. Now I'll draw lines on the substrate

It is too high to draw vertically. You can clip a corner ruler on the back of the mountain, and the straight side of the base plate is drawn against the corner ruler

The veteran can ignore this step when drilling the positioning hole with the center drill, but I'm afraid that the technology is not enough. If you use the drill directly, you'll miss it. Let's take one more step

Then use a drill to drill through. If I want to use a 6mm countersunk screw in the future, I will drill a 6mm hole

Turn out counterbore with spot facer

Continue to draw the position of the graphite hole and punch the positioning hole. The distance between my two lines is 5mm, and the graphite column used is 5mm

Drill positioning hole with center drill

Use a 5.1mm drill to drill holes. Don't punch through this hole. The copper bar I use is 6mm thick, so I will drill it to a depth of 5.0-5.5mm;

Let's turn on the flash and see if it's golden

Next, we start to inlay graphite columns. Here, we need to use anaerobic glue. There are many models of anaerobic glue. Here, we need to use the glue to bond the columns

All the glue can be filled into the graphite column without fear of solidification. The anaerobic glue will not solidify when there is air, and will solidify only when the gap is less than 0.25mm. Therefore, the preservation of anaerobic glue can not be sealed. This anaerobic glue can also be used to stick belt pulleys, so that there is no need to open keyways or jackscrews on the belt pulleys.