IGraphite mouldThe coarse structure after quenching will seriously affect the mechanical properties of the graphite mold, which will cause fracture of the graphite mold and seriously affect the service life of the graphite mold.

The reasons are as follows:

(1) the graphite mold steel is confused, and the actual steel quenching temperature is far lower than the required quenching temperature of the graphite mold material (for example, GCr15 steel is treated as 3Cr2W8V steel).

(2) graphite die steel is not properly spheroidized before quenching, and the spheroidized structure is poor.

(3) the quenching heating temperature of graphite mold is too high or the holding time is too long.

(4) the graphite mold is improperly placed in the furnace, which is easy to overheat in the area near the electrode or heating element.

(5) for graphite molds with large cross-section changes, improper selection of quenching and heating process parameters will cause overheating at thin sections and sharp corners.

Five elements of preventive measures

(1) steel shall be strictly inspected before being put into storage to prevent confusion.

(2)VC sintered graphite mouldCorrect forging and spheroidizing annealing shall be carried out before quenching to ensure good spheroidizing structure.

(3) correctly formulate the quenching and heating process specifications of graphite molds, and strictly control the quenching and heating temperature and holding time.

(4) regularly inspect and calibrate temperature measuring instruments to ensure normal operation.

(5) when the graphite mold is heated in the furnace, it should keep an appropriate distance from the electrode or heating element.

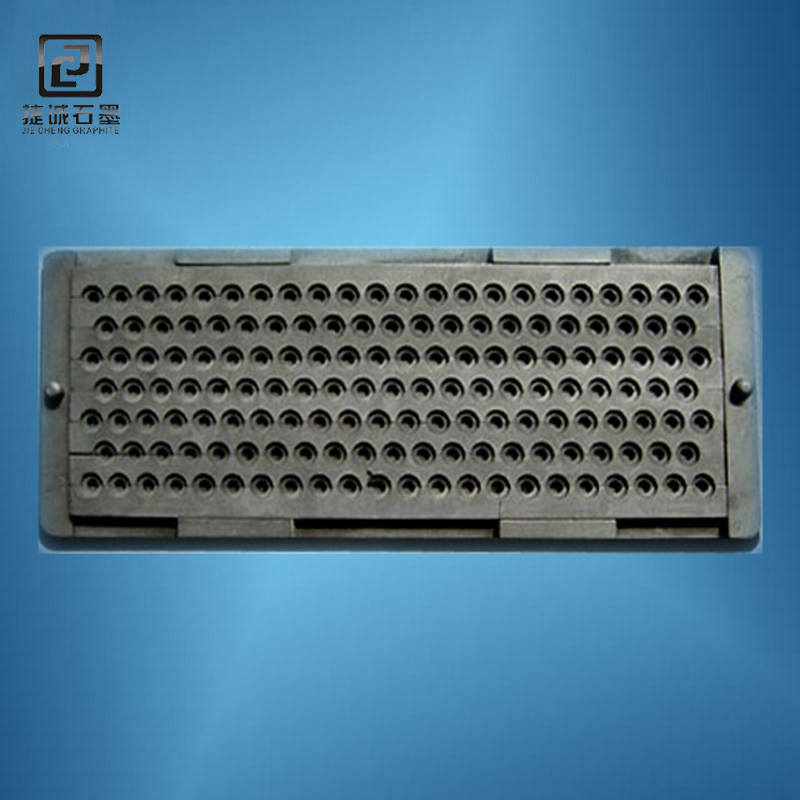

Sintered graphite mould

2、 The structure of the graphite mold is poor before heat treatment. The final spheroidized structure of the graphite mold is coarse and uneven, and the spheroidization is not perfect. The structure has network, band and chain carbides, which will make the graphite mold easy to crack after quenching and cause the graphite mold to be scrapped.

The causes are as follows:

(1)Graphite mouldSerious carbide segregation exists in the original structure of steel.

(2) poor forging process, such as high forging heating temperature, small deformation, high forging stop temperature and slow cooling speed after forging, makes the forging structure coarse and there are network, band and chain carbides, which is difficult to eliminate during spheroidizing annealing.

(3) the spheroidizing annealing process is not good, such as the annealing temperature is too high or too low, and the isothermal annealing time is short, which can cause uneven spheroidizing annealing structure or poor spheroidizing.

Five elements of preventive measures

(1) Generally, graphite die steel materials with good quality shall be selected as far as possible according to the working conditions, production batches and the strength and toughness properties of the materials themselves.

(2) Improve forging process or adopt normalizing preparation heat treatment to eliminate network and chain carbides and non-uniformity of carbides in raw materials.

(3) High carbon graphite die steel with severe carbide segregation that cannot be forged can be subjected to solution refining heat treatment.

(4) The correct spheroidizing annealing process specification for the forged die blank can be formulated, and quenching and tempering heat treatment and rapid and uniform spheroidizing annealing can be used.

(5) Charge the furnace reasonably to ensure the uniformity of the mold blank temperature in the furnace.

Related reading:Causes of defects in heat treatment of graphite mould and preventive measures (II)