The application of graphite products is very wide. After all, there are many kinds of products, such as graphite crucibles, graphite rods, graphite plates, graphite connecting pieces, graphite molds, and so on. There are too many, so Xiaobian will not write them one by one, mainly to talk with youApplication of graphite mould:

The mold is what we usually call the model. Because graphite products have good electrical and thermal conductivity, they are used in continuous casting of copper, continuous casting of copper and continuous casting of other metals.

Then let's talk about the use of graphite molds in modern industry:

(1)Graphite mould for glass forming:

Chemical stability is one of the most important properties of graphite materials. In addition, graphite molds are not easy to be infiltrated by molten glass, and will not change the composition of glass. Graphite materials have good heat-resistant impact performance and small size change with temperature. Therefore, in recent years, they have become indispensable mold materials in glass manufacturing. They can be used to make glass tubes, bends, funnels and other molds of various special-shaped glass bottles.

(2) Continuous manufacturing and semi continuous manufacturing of non-ferrous metals:

Because the continuous (semi continuous) smelting metal state is directly used for the promotion of advanced smelting methods such as bars and pipes, the smelting of copper alloy, aluminum, aluminum alloy and other metals has taken the lead in following this method. people

Graphite is considered the most suitable material for continuous casting and semi continuous casting because of its unique thermal conductivity and conductivity. The actual experience in production proves that because of the excellent thermal conductivity of the graphite mold (better thermal conductivity can make the metal or alloy solidify faster), the lubricity of the graphite mold itself is very good, which accelerates the casting speed.

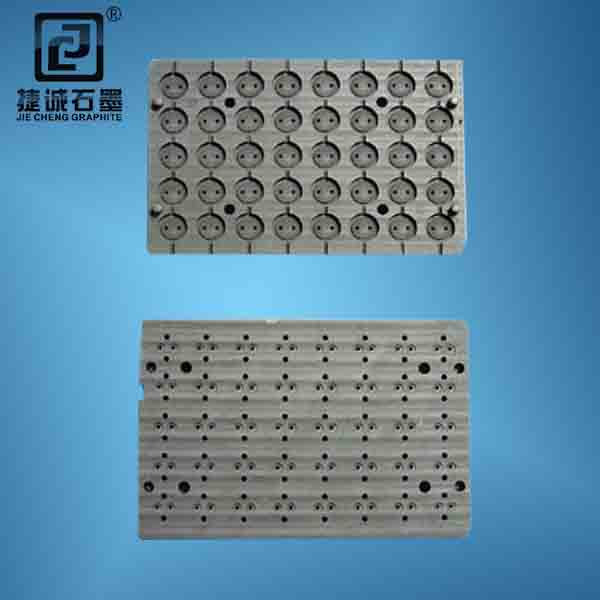

(3) Graphite mold for centrifugal casting:

Graphite graphite mold has been successfully used in centrifugal casting. The use of graphite mold in centrifugal casting has greatly accelerated the efficiency and product quality of centrifugal casting.

(4)Graphite mould for pressure casting:

There has been a consensus on the use of artificial graphite materials in pressure casting of non-ferrous metals. For example, the copper alloy produced by the pressure casting mold for pressure casting and new customers have been used in the production of precision parts, automobiles and machinery.

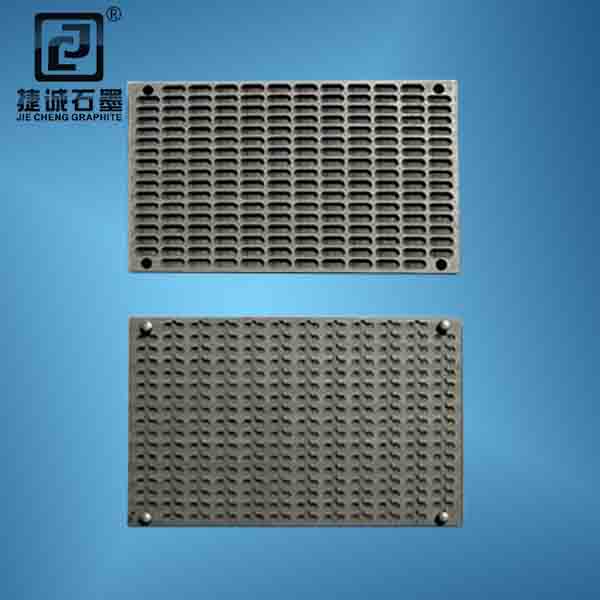

(5) Graphite mold is used for hot pressing die:

The artificial graphite hot pressing die has the following characteristics when it is used for pressure sintering of cemented carbide: first, if the pressing temperature is increased to 1350-1450 degrees, the required unit pressure can be reduced to 67-100 kgf / cm2 (that is, 1 / 10 of the cold pressing pressure); Second, the pressing and heating are carried out in the same process, and the compact sintered body can be obtained after a short time of sintering.

The above five points are what Xiaobian knowsGraphite mouldIn fact, there will be more in the future.