along withGraphite bearingWidely used in mechanical equipment, carbon bearing developed on the basis of metal bearing. Carbon bearings have different characteristics from metal bearings, such as self lubrication, high temperature resistance, corrosion resistance, light weight, etc. With the development of science and technology, graphite bearings have also been further expanded, and bronze graphite oil bearing and inlaid graphite bearing have been manufactured. It provides more space for bearing selection under various working conditions and meets the requirements of different technical conditions. In addition, carbon composite bearing will be the development direction of bearing materials in the future due to its designability and unique material functions.

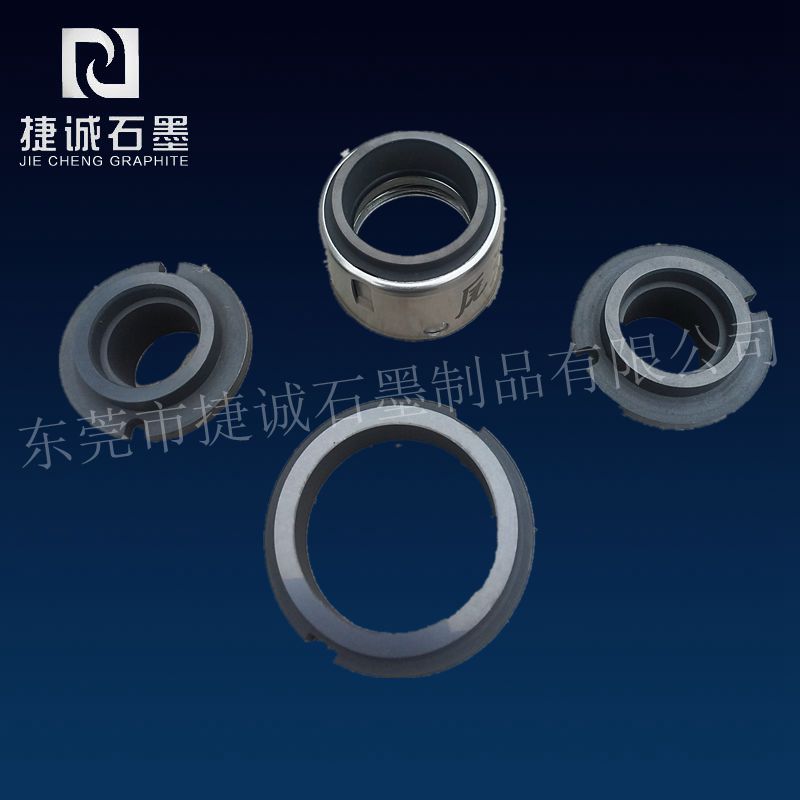

The design types of graphite bearings include cylindrical, cylindrical instead of flange, circular and special structures. However, considering the strength of graphite bearings, the thickness of carbon bearings must be larger than that of metal bearings. The thickness should be 1 / 5-1 / 7 of the inner diameter. The minimum is more than 3mm. The length of bearings is more than twice the inner diameter. The temperature of the bearing will rise during operation, and the operating clearance can be determined according to the thermal expansion of the shaft and the bearing, generally about 0.3% of the shaft diameter.

Powder metallurgy is used for the production of bronze graphite oil bearing. In order to increase the bearing load, iron powder is added to the new bronze graphite oil bearing.

The manufacturing process of carbon graphite bearings is basically the same as that of other carbon products. The basic process includes: selection of raw materials, pretreatment of raw materials, crushing of raw materials, screening and classification, batching of granular and powdered materials, selection of binders, mixing, kneading, rolling, grinding, pressing, baking, graphitization treatment of artificial graphite products, immersion, mechanical processing, etc, In order to increase mechanical strength and impact resistance, some graphite bearings need to be impregnated with metals (such as antimony, copper, lead, etc.) to finally achieve the required technical performance, and then machined to the required geometric size.

There are two manufacturing methods for inlaid graphite bearings. The first is the casting method, in which the graphite slider with the processed geometric size is distributed in the casting mold according to the design, and then cast with molten metal, and then machined to the required size. The second is to process some holes on the metal substrate according to a certain arrangement, and then uniformly mix graphite, MoS2 and binder in a certain ratio to make lubricant, solidify in the holes, and achieve the required size after processing, inlayGraphite bearingThe compressive strength and thermal expansion coefficient of generally depend on the metal material.