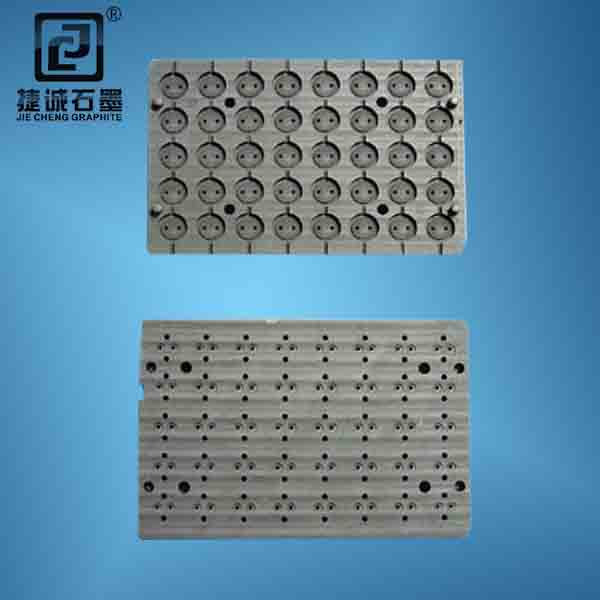

Graphite mould, steel casting graphite mould, steel casting graphite mould

Steel casting graphite mold mainly refers to the good performance of graphite. Generally speaking, graphite's high-temperature resistance, corrosion resistance, chemical stability, thermal shock resistance and other functions are the prerequisite for graphite to enter the mold industry. At the same time, graphite is also used in graphite molds for continuous casting and semi continuous casting of non-ferrous metals.

In recent years, advanced production methods such as directly continuous (or semi continuous) production of bars or tubes from the molten metal state are being promoted at home and abroad. This method has been used in copper, copper alloy, aluminum and aluminum alloy in China. Artificial graphite is considered as the most suitable material for continuous casting or semi continuous casting molds of non-ferrous metals.

The production practice has proved that the graphite mold not only improves the casting speed due to its good thermal conductivity (which determines the solidification speed of metal or alloy) and good self-lubricating performance, but also can be directly processed in the next process due to its accurate size, smooth surface and uniform crystal structure. This not only greatly improves the yield and reduces the waste loss, but also greatly improves the product quality.