Graphite raw materials are very rich in Heilongjiang, but they are often producedGraphite productsCompared with foreign countries, there is still a certain gap. What is the reason? Next, Xiaobian will work with you to understand the reasons through raw materials, processes and manufacturers:

First of all, we should know that China's imported graphite products mainly include isostatic pressure graphite, flexible graphite and graphite electrode.

1. Gap between isostatic pressing graphite in China and abroad

Isostatic pressing graphite is one of the finest graphite materials, which is closely related to high-tech and national defense cutting-edge technologies. It is one of the most valuable new materials in the 21st century.

Although China has its own isostatic pressing graphite production enterprises, most of the isostatic pressing graphite products have low performance, single variety, and large-scale high-performance isostatic pressing graphite can not be mass produced.

The development of isostatic pressing graphite materials abroad has a long history. Among them, the isostatic pressing graphite produced by Japan, the United States, Germany and France has nearly a hundred models and self-made series, providing a large number of new types of graphite products for the development of other high-tech fields.

Relatively speaking, the development of isostatic pressing graphite materials in China is restricted by the following aspects.

(1) Gap between raw materials and formula

The raw materials for producing isostatic pressure graphite in China are basically the same as those used for other graphite products, namely petroleum coke and asphalt coke. The specific production raw materials and formulas of foreign countries have always been confidential to China.

After acquiring Shanxi Quanhai carbon company in 2007, sigli established sigli Quanhai carbon (Shanxi) Co., Ltd. As far as the current situation is concerned, sigli's production base in China only uses the two processes of roasting and graphitization for production.

Roland France has invested in the construction of a 2500 t / a isostatic pressing graphite material production base in Chongqing. The production base is not a complete production line, and its key processes such as abrasives, formulations, kneading, granulation and other key processes have not been set up in Chongqing.

These foreign-invested multinational companies still put the core material formulation process of isostatic pressing graphite material production in China. This is a constraint and test for the development of isostatic pressing technology in China.

(2) Gap in production process

The production process of isostatic pressing graphite materials in China has more steps than that in foreign countries, and the degree of automation and yield are low, so the productionGraphite productsThe cost is high.

If we want to catch up with developed countries, we must start from hardware equipment to process flow, and further study foreign related processes to improve.

(3) Gap in product specifications

At present, large and super large isostatic pressure isotropic graphite is a gap in China's graphite products. In Japan, isotropic graphite with a diameter of 2500mm can be produced, and the diameter of sigli's products can also reach 1250mm. Chongqing Roland special graphite Co., Ltd. can produce isostatic graphite with a maximum diameter of 1500mm and a maximum length of 2m. However, there are few large-scale isotropic graphite in China. However, China's isostatic graphite products with a diameter of less than 500mm have excess capacity, but products with a diameter of more than 600mm cannot be produced.

In addition, such production equipment is also difficult to match, and the product quality is difficult to stabilize. This is the gap between Chinese enterprises and those of developed countries.

In terms of raw materials, formula, production process and equipment, China's isostatic pressing technology still has a long way to go.

At present, China imports about 3 / 4 of its consumption of static pressed graphite billets from abroad every year, and the consumption is increasing year by year. China is undoubtedly a potential isostatic pressing graphite Market in the world. The development of isostatic pressing graphite products has only a history of 10 years in China, and is still in its infancy.

(4) Gap between manufacturers

The isostatic pressure graphite produced by domestic manufacturers is low in output, quality, performance, product size and specification, and can not fully meet the market demand. Most of them are low-end small-size products, which have a large gap with the products of major foreign manufacturers. The specific performance is that the size is small, the strength and density are not enough, and the most important difference is the non-uniformity of the material structure and performance.

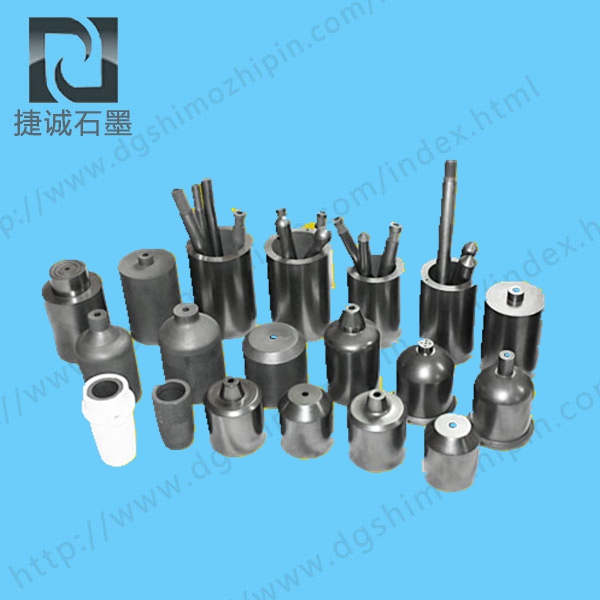

For graphite products, whether they are Shenzhen graphite products, Dongguan graphite products, Henan graphite products, Zhengzhou graphite products and other places, they are almost the same. These gaps are mainly due to the fact that the selection of raw materials and production technology have not reached the advanced level. Almost all high-end special graphite is imported, mainly from the four isostatic pressure graphite production bases of the United States, Japan, Germany and France. Therefore, in the research field of isostatic pressing graphite, China needs to invest more work. At the same time, our company also makes unremitting efforts to make a lot of efforts in raw materials. We can't import isostatic pressing graphite. Customers who need it are welcome to customizeIsostatic pressing graphite products。

Company telephone: 0769-89392518

Company fax: 0769-89392508

Mr. He: 13602898588

Address: Dongguan Jiecheng graphite products Co., Ltd., No. 3, Caimei 2nd Road, longjiantian, Huangjiang Town, Dongguan City